Artificial Intelligence (AI) is no longer a distant concept. It’s here, transforming industries, and manufacturing is no exception.

AI advancements in manufacturing are reshaping the sector. They’re turning traditional factories into smart factories. These factories are more efficient, more productive, and more adaptable to change. But what exactly are these advancements? How are they integrated into manufacturing software? And what benefits do they bring to the table?

In this article, we’ll explore these questions. We’ll delve into the world of AI in manufacturing, from predictive maintenance to quality control automation. Whether you’re a manufacturing professional, a tech enthusiast, or just curious, this article will provide valuable insights. So, let’s dive in and explore the top AI advancements in manufacturing.

Understanding AI in Manufacturing

Artificial Intelligence, or AI, refers to the simulation of human intelligence in machines. These machines are programmed to think like humans and mimic their actions. In the context of manufacturing, AI can analyze data, make decisions, and perform tasks more efficiently than humans.

AI advancements in manufacturing include machine learning, robotics, and cognitive computing. These technologies help manufacturers predict failures, automate quality control, and optimize supply chains. They’re transforming the way manufacturers operate, leading to increased efficiency and productivity.

The Emergence of Smart Factories

Smart factories represent the next leap in manufacturing. They leverage AI, the Internet of Things (IoT), and other advanced technologies to create a fully integrated, collaborative system. This system can self-optimize performance across a broader network, making real-time decisions about productivity.

These factories are characterized by their adaptability, efficiency, and ergonomics. They can respond in real-time to meet changing demands and conditions in the factory, in the supply network, and with customer needs. The emergence of smart factories is a testament to the transformative power of AI advancements in manufacturing.

Key AI Advancements Shaping Manufacturing

AI advancements are revolutionizing the manufacturing sector. They are driving efficiency, reducing downtime, and enabling more precise control over processes. AI technologies are also helping manufacturers to make more informed decisions based on real-time data.

Machine learning, robotics, quality control automation, and supply chain optimization are among the key AI advancements in manufacturing. These technologies are transforming traditional factories into smart factories. They are enabling manufacturers to predict, automate, and optimize operations to a degree that was previously unimaginable.

Here are some of the key AI advancements that are shaping the manufacturing sector:

- Machine Learning and Predictive Maintenance

- Robotics and Automation

- Quality Control Automation

- Supply Chain Optimization

Machine Learning and Predictive Maintenance

Machine learning, a subset of AI, is being used to predict equipment failures and schedule maintenance. This predictive maintenance helps to prevent costly downtime and extend the life of machinery. Machine learning algorithms analyze historical and real-time data from machine sensors to identify patterns and predict future outcomes.

By predicting equipment failures before they happen, manufacturers can schedule maintenance during non-productive times. This reduces downtime, increases productivity, and lowers maintenance costs.

Robotics and Automation

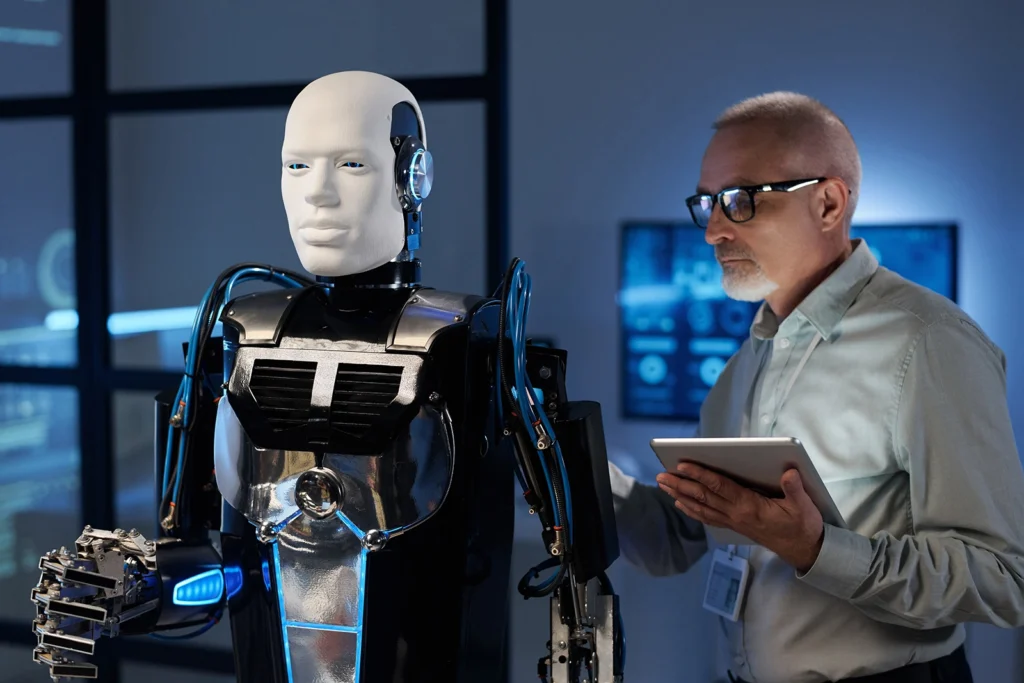

Robotics and automation are key AI advancements in manufacturing. Robots can perform repetitive tasks more quickly and accurately than humans. They can also work in hazardous environments, improving worker safety.

AI-powered robots can learn from their experiences, adapt to new tasks, and work collaboratively with humans. They can perform complex tasks that require precision, flexibility, and adaptability. AI-powered robots can also take on repetitive tasks that can free up time for humans to focus on more complicated tasks and issues. This increases efficiency and productivity in the manufacturing process.

Quality Control Automation

AI is transforming quality control in manufacturing. Automated inspection systems use AI algorithms to detect defects and anomalies in products. These systems can inspect products more quickly and accurately than human inspectors.

AI-powered quality control systems can learn from their mistakes and improve over time. They can also adapt to new products and inspection criteria. This reduces the risk of defects and improves the overall quality of products.

Supply Chain Optimization

AI is being used to optimize supply chains in manufacturing by analyzing vast amounts of data to predict demand, optimize inventory, and streamline logistics. This helps manufacturers to reduce costs, improve efficiency, and respond more quickly to changes in demand.

AI-powered supply chain systems can also identify risks and opportunities in the supply chain, and make recommendations to improve performance and resilience. This helps manufacturers to stay competitive in a rapidly changing market.

Integrating AI with Manufacturing Software

The integration of AI with manufacturing software is a key aspect of the digital transformation in the industry. Manufacturing software systems, such as Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES), are now incorporating AI capabilities to enhance their functionalities.

AI-powered manufacturing software can analyze vast amounts of data from various sources in real-time. This allows for more accurate forecasting, better decision-making, and improved operational efficiency. Furthermore, AI can automate routine tasks, freeing up human workers to focus on more complex and strategic tasks. This integration is paving the way for more intelligent and efficient manufacturing processes.

The Benefits of AI in Manufacturing

As you can see, the benefits of AI in manufacturing are numerous and transformative. AI can significantly increase efficiency and productivity by automating routine tasks and optimizing production processes – leading to substantial cost savings and improved product quality.

Moreover, AI can enhance decision-making through predictive analytics and real-time data analysis, allowing manufacturers to anticipate issues, manage risks, and make informed decisions. AI can also contribute to sustainability efforts by optimizing resource usage and reducing waste, making AI an invaluable tool in the modern manufacturing landscape.

Overcoming Challenges in AI Adoption

Despite the clear benefits, adopting AI in manufacturing is not without its challenges. One of the main hurdles is the need for significant investment in technology, infrastructure, and workforce training. Manufacturers also need to address data security and privacy concerns, which are paramount in the era of Industry 4.0.

However, these challenges can be overcome with strategic planning, collaboration, and continuous learning. Manufacturers need to adopt a long-term perspective, focusing on building robust data management systems, fostering a culture of innovation, and investing in employee training. With the right approach, the potential of AI in manufacturing can be fully realized.

The Future of AI in Manufacturing

The future of AI in manufacturing is promising, with advancements expected to revolutionize the entire production process. From autonomous vehicles and advanced robotics to cognitive computing and real-time data analysis, AI is set to bring about unprecedented changes in the manufacturing sector.

Moreover, as AI technologies continue to evolve, they will enable more efficient production planning, inventory management, and quality control. They will also facilitate remote monitoring and control of manufacturing processes, thereby enhancing operational efficiency.

Conclusion: Embracing AI for Manufacturing Excellence

In conclusion, embracing AI advancements in manufacturing is no longer an option but a necessity for businesses to stay competitive. By integrating AI with manufacturing software, optimizing processes, and overcoming adoption challenges, companies can achieve manufacturing excellence and pave the way for a more sustainable and efficient future.